We’ve been repairing reticulation for around 20 years, and we’ve seen the good, the bad, and the ugly. Here’s a comprehensive list of common problems and solutions to these problems which you can use to try and problem-solve yourself. Remember, if you get stuck, reach out to us and we’ll see what we can do to help you. It’s always better to be proactive rather than reactive when it comes to these things. If you’re thinking of installing reticulation or doing it properly the first time, please reach out to us.

Ultimate Guide to Reticulation Repairs

Common Sprinkler Issues That Need Repairing

Sprinklers Broken At The Base

This issue often arises when sprinklers are installed at incorrect heights, making them susceptible to damage from heavy objects passing over, such as vehicles, rocks, or lawnmowers. To avoid such damage, it’s crucial to ensure that lawn sprinklers are installed below ground level, where they are safe from mowers. In situations where sprinklers are prone to impact, installing larger sprinklers and using flexible, adjustable fittings like articulated risers can be beneficial. These risers act like suspension for your sprinklers, absorbing the downward force and reducing the risk of damage. This technique is also applicable for garden risers that are frequently hit and snapped.

Sprinklers Not Covering Like They Used To

Conducting a pressure test is the first step to diagnosing this issue. If the entire system is experiencing low pressure, the problem may lie with the master solenoid or a rusted isolation tap. It’s also advisable to compare your water pressure with that of your neighbours to identify discrepancies that might indicate issues with your water meter or main piping. Sometimes, the cause can be as simple as the water pressure in the suburb being reduced as part of common utility practices.

Sprinklers Leaking All the Time

Constant leaking usually points to a problematic solenoid that may need replacement. However, before proceeding with replacement, check if the solenoid has been accidentally turned to the manual on position, which can cause continuous leaking.

Sprinklers Leaking at the Base or Bubbling from the Ground

This problem typically occurs when the connection between the sprinkler and the piping is compromised, either due to impact or the use of low-quality connections. Replacing the damaged connection with a higher-quality one is often necessary. Implementing solutions such as using articulated risers or adjusting the height of the sprinkler can also mitigate this issue.

Sprinklers Leaning Over

Ensuring that garden risers are deeply embedded and that sprinklers are vertically aligned is crucial for both aesthetics and functionality. Articulated risers can aid in easily adjusting and straightening sprinklers during installation.

Sprinklers Shooting Up in the Air

This typically requires the replacement of the damaged sprinkler head and ensuring that sprinklers are positioned in areas where they are less likely to be damaged.

Sprinklers Blocked

The immediate solution is to unblock or flush out the sprinkler. If the nozzle cannot be cleared, replacement might be necessary. Soaking the nozzle in dishwashing liquid can sometimes help to dissolve the blockage.

Sprinklers Buried and Lost

To locate buried sprinklers, run the irrigation system for a full cycle and walk over the suspected area. The presence of squelching or the feel of the sprinkler underfoot can indicate its location. If unsuccessful, professional services like those offered by Retic Renovation can assist in locating them.

Sprinklers Not Turning On

If a section or the entire system fails to activate, troubleshooting will involve checking for controller signal issues, damaged solenoid valves, or wiring problems. Additionally, ensure that the main irrigation connection tap (isolation tap) is turned on.

Sprinklers are Stuffed

For irreparable issues, contacting Retic Renovation for professional assistance is recommended.

Common Pressure Issues That Need Repairing

Low Pressure on System

Experiencing low pressure across your entire reticulation system requires a systematic approach to diagnose. Start with a pressure test at your home and then compare it with your neighbor’s system to identify any discrepancies. Inspect the sprinklers on each station to ensure they receive adequate pressure and flow from the mains, considering their spacing. A widespread pressure drop in your suburb could be the root cause. If your pressure differs significantly from your neighbor’s, the issue may lie with your main supply line, water meter, a rusted isolation tap, a blocked master valve, or a loss of pressure in your bore system. Conducting these tests methodically is crucial to pinpointing the exact problem without unnecessary interventions.

Low Pressure on One Section

Begin with a pressure test from the mains for the affected section. Assess if the sprinklers on that station are compatible with the available pressure and flow. The issue could stem from a faulty solenoid, a leak in the piping, or even tree roots obstructing the pipe. Addressing low pressure on a specific section often involves a process of elimination and may require some time to resolve accurately.

Drop in Pressure Compared to Normal

Similar to addressing low pressure on the entire system, start with pressure tests from your home and compare with neighbors’. Check the master valve, isolation tap, and water meter for any issues that could be causing the drop in pressure. Systematic testing is essential to identify the source of the problem.

Low Pressure on Specific Sprinklers

If only certain sprinklers on a station are affected, consider whether this has been a longstanding issue or a recent development. Factors such as smaller pipes leading to specific sprinklers, blockages, or tree root interference could be to blame. A slight overall pressure drop might also affect some sprinklers more than others. Conducting a pressure test can help identify blockages or other causes of reduced flow to these sprinklers.

High Blood Pressure Because Reticulation is Causing Issues

For frustrations and stress caused by ongoing reticulation problems, seeking professional assistance from Retic Renovation can provide relief and ensure your system is functioning optimally.

Common Solenoid Issues That Need Repairing

Solenoids Not Turning On

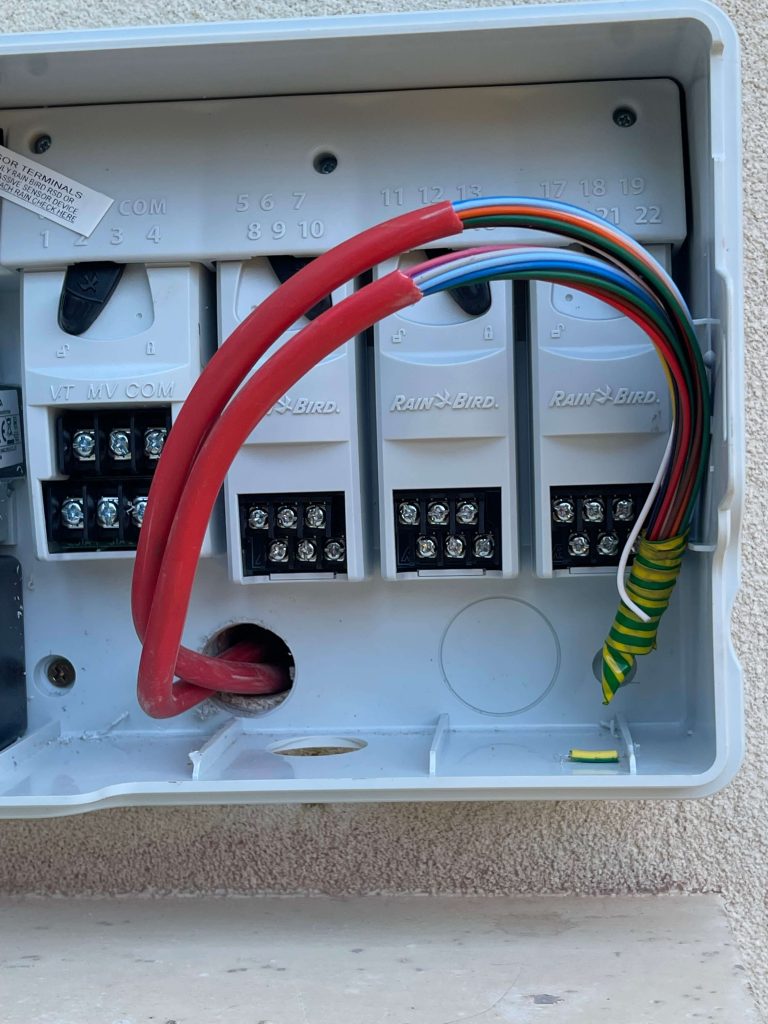

A less frequent issue that can arise is the controller not sending signals to specific solenoids, or sometimes not sending a signal at all. First, verify that the controller is receiving power from the main 240V AC supply and that it’s sending the correct signals to the solenoids. Using specialized diagnostic tools can help identify whether the issue lies with a broken wire, the solenoid itself, or another electrical problem. Always ensure the controller has power by checking if the display remains active without the backup battery; if it goes blank, the unit is likely not receiving power. For safety, never attempt to modify or repair hardwired electrical connections yourself—always engage a licensed electrician for these tasks.

Solenoids Are Not Easily Accessible

Solenoids should be housed within visible, easily accessible boxes, often referred to as spotter boxes. Avoid placing solenoids under concrete, trees, or in hard-to-reach locations. Organize solenoids into logical groups based on their location on the property (e.g., front yard, back yard, etc.) to simplify maintenance and troubleshooting.

Solenoids Are Not Easily Accessible

Utilize a professional-grade solenoid locator, such as the Pro 900 solenoid tracker, to find hidden or buried solenoid valves effectively.

Solenoid Boxes Are Broken or Unsightly

Replace damaged or unsightly solenoid boxes with durable commercial-grade solenoid boxes and manifolds like the Enkei solenoid manifold. Choose installation locations carefully to avoid areas prone to damage or obstruction.

Solenoids Turn On With All the Other Solenoids

This usually indicates a sticking solenoid that needs replacement. Before doing so, check if the solenoid has been manually activated. Ensure all components on the solenoid are secured tightly to prevent unintended activation.

Some Solenoids Come On and Others Don’t

This problem is often related to wiring issues or the controller failing to send signals. While blockages and roots can also cause issues, electrical problems are more common and should be investigated first.

Solenoids Are Under Trees

Relocate solenoids away from tree roots to prevent damage and ensure easy access. Reconnect the solenoids to the main piping, ideally routing around obstructions.

Solenoids Are Under Concrete or Paving

When laying piping under concrete, avoid using joins. Instead, use continuous lengths of blue line plumbing piping within a protective sleeve. If solenoids must be accessed under concrete or paving, cutting the concrete may be necessary. Planning for a permanent access solution, such as installing a sleeve that allows for the easy removal and maintenance of pipes, is advisable.

Solenoids Leaking Continuously

Continuous leaks from a solenoid typically necessitate its replacement to restore proper function to the reticulation system.

Solenoids Are Stuffed

For solenoids that are beyond repair, contacting Retic Renovation for professional assistance is recommended to ensure a swift and effective resolution.

Common Reticulation Wiring Issues That Need Repairing

Get Proactive

Before we look into specific wiring issues it is worth ensuring your irrigation wiring is correctly installed from the outset which can prevent many common problems – if you are installing reticulation and wish to avoid these issues please reach out to us.

- No Joins in Wiring: Always opt for a continuous run of wiring from the controller to the valves. This strategy isolates potential issues to easily accessible valve boxes and controllers.

- Use of Conduit: Install wiring within a conduit to protect it from damage during digging and make it more visible. For added visibility (and a bit of humour), consider using orange conduit.

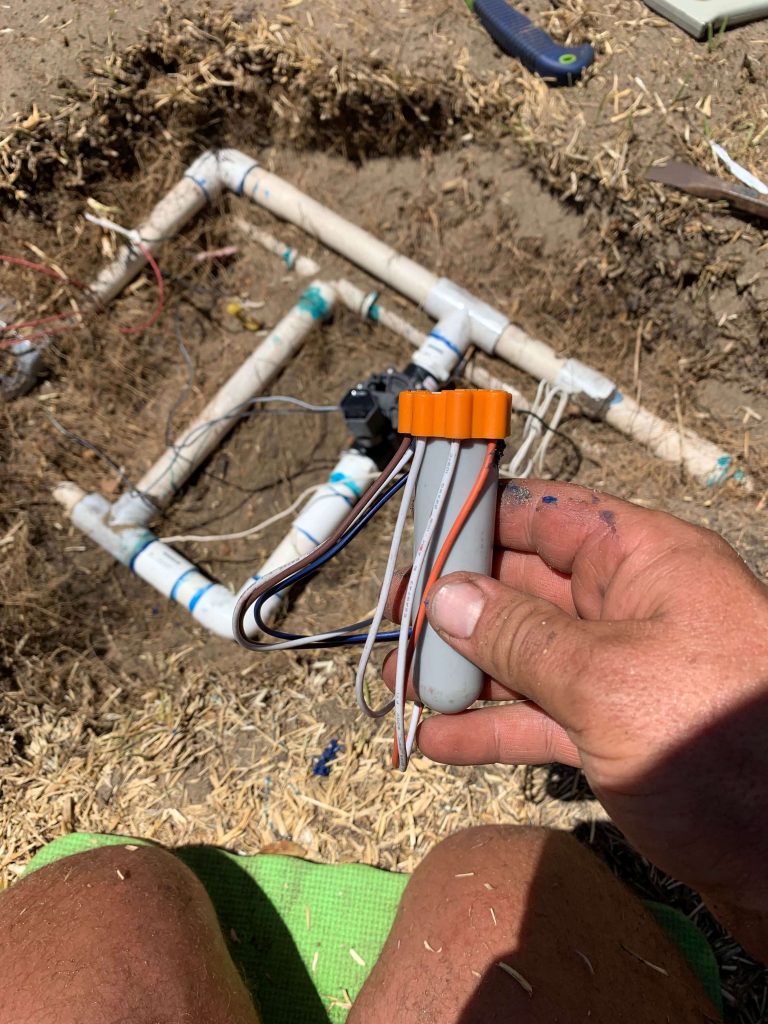

- Waterproof Gel Connectors: Employ silicon gel connectors at joins to encapsulate and protect from water ingress, thus preventing shorts.

- Avoid Problematic Locations: Do not run wiring under large trees or in hard-to-access areas to simplify future maintenance.

Reticulation Wiring is Cut or Broken

Utilize problem-solving tools designed to track and locate cut or broken wiring. Ideally, rewiring should be done if the initial setup was improper. For necessary repairs, mark the repair location, place it within a solenoid box, and take a picture for records. Always use waterproof gel connectors for any joins.

Reticulation Wiring is Corroding

Wiring corrosion often results from exposure to the elements, including sunlight. Burying the wiring in conduit and using waterproof gel connectors can prevent this issue by ensuring the wiring is not directly exposed to harsh conditions.

Reticulation Wiring Joins are Breaking or Failing

Avoid merely twisting wires together or using tape. These methods are prone to moisture ingress, leading to brittle wires and signal failure. Instead, use waterproof gel connectors to ensure a durable and moisture-resistant connection.

Can’t Locate Reticulation Wiring

Employ a professional-grade solenoid tracker to locate hidden or buried wiring efficiently.

Reticulation Wiring Needs Relocating

When relocating wiring, especially in the context of new installations like pools or concrete, run a new section of wiring in conduit without joins under the new structure. Mark any necessary joins and ensure they remain accessible to avoid future complications. This approach helps avoid the double expense typically associated with correcting improperly done work in established landscapes.

Common Issues With Leaking That Need Repairing

Leaking Pipes

- Constant Leaks: If leaks occur non-stop, investigate the solenoid as the likely cause, requiring replacement to stop continuous water flow. The system should only leak when active.

- Cause of Breakage: Determine why the pipe broke; issues could include being too close to the surface or external pressures. Consider relocating and improving the placement of the piping.

- Quality of Repairs: Use high-quality PVC glue, such as Christie’s Red Hot Blue Glue, and ensure proper application with the correct clamps and spacing for durable joins.

Piping Broken Under Concrete, Paving, Trees or Needs Relocating

Use blue line plumbing piping or strong class 12 PVC inside stormwater piping as a protective sleeve for areas under hard surfaces. This setup facilitates easier replacement and maintenance without the need for joins under concrete or similar materials.

Can’t Find Piping

Engage professionals like Retic Renovation to locate and assess the issue with the hidden piping.

Piping is Damaged or Crushed

Redirect the water flow around the damaged area, usually tracing from low to high pressure to locate the compromised section.

Piping is Splitting

Replace the affected section of piping. Once splitting begins, it typically worsens, necessitating the removal and replacement of the compromised section.

Common Issues With Reticulation Controllers That Need Repairing

Controller Knob or Dial is Spinning or Not Adjusting Settings

Replace the controller. Attempting repairs on a malfunctioning controller, especially if parts are unavailable or the model is outdated, is often not cost-effective. Installation of a new controller by a licensed electrician is recommended for efficiency and safety.

Controller Turning Some Stations On But Not Others

Verify the controller’s signal to the affected stations. If the display indicates functionality but the stations remain inactive, the issue may lie with a broken wire or damaged solenoid, necessitating further diagnostics with specialized tools.

Controller Buttons Not Working

Follow the initial troubleshooting steps mentioned for spinning or non-adjusting dials, as these issues often share common solutions.

Controller Coming On Multiple Times Per Day

Review and adjust the controller settings. Misconfigured programs, days, start times, and run times can lead to multiple activations. Consulting the manual and ensuring settings are correctly applied can resolve this issue.

Retic Controllers Not Turning System On

Check for power to the controller. Removing the battery to see if the display remains active can diagnose a power issue. Always consult a reticulation specialist or licensed electrician for electrical concerns.

Controller is Outdated and Missing Functions

Consider manual operation on designated watering days or upgrade to a new controller with the required functionalities to comply with local watering restrictions.

Controller Door is Broken; Panel is Faded

Proactively replace the controller to avoid complications. Dealing with minor issues early can prevent more significant problems later.

Common Issues With Drip Line Systems That Need Repairing

Drip Irrigation Not Functioning Well (Plants Struggling)

It’s crucial to ensure that the drip lines are not blocked and that the system includes all necessary components for optimal functionality. A well-designed system should include a filter at the start, an air release valve or vacuum breaker to prevent dirt suction, and a flush valve at the end to clear debris. Ensure there are enough drippers, properly spaced, to provide uniform coverage.

Ensuring Adequate Drip Line Coverage

Adequate coverage is key to a healthy garden. Drip lines should be spaced at a minimum of 30 centimeters apart to ensure a consistent blanket area coverage. For trees or more thirsty bushes, additional rings of drip line are essential to meet their water needs. Specifically, fruit trees and other high-water-demand plants require extensive drip line coverage around the entire root zone to thrive. This approach ensures that every part of your garden receives the right amount of water, minimizing stress on the plants and promoting vigorous growth.

Drip Line Blocking Up

Regularly check the water source quality and ensure that your drip irrigation system is equipped with the necessary components, such as filters and flush valves. In some cases, parts of the drip line may need to be replaced, especially if the system is old and showing signs of wear.

Drip Line Leaking

If the drip line is leaking, it often indicates physical damage, such as cuts. A professional inspection can help identify the exact cause and determine the best course of action for repairs.

Drip Line Visible on Top

To maintain the aesthetic appeal of your garden and protect the drip line, cover any exposed sections with mulch. This not only hides the irrigation system but also contributes to soil moisture retention.

By addressing these common issues with detailed solutions, your drip irrigation system will be more efficient, ensuring your plants receive the water they need without waste or excess.

Common Issues With Drippers That Need Repairing

Drippers Blocking Up

To prevent blockages, install a flush valve at the end of your irrigation line. This helps remove any accumulated dirt within the drippers, ensuring they continue to function efficiently.

Drippers Not Doing the Job

Solution: Plants with extensive root systems or those requiring more water, such as large trees, may need additional drippers. Ensure you’re providing enough water by installing extra drippers or drip lines around these plants to cover their entire root zone effectively.

Can’t Locate Drippers

If you’re having trouble finding your drippers, follow the line they run off and dig gently along it. This approach helps uncover the tubing, allowing you to locate and adjust the drippers as needed.

Common Coverage Issues That Need Repairing

Brown Patches in Lawns

Brown patches in lawns typically signal uneven water coverage or insufficient watering. To combat this issue, consider the following strategies:

- Improving Soil Moisture Retention: Use a high-quality wetter soil to enhance the soil’s ability to retain water, which is especially beneficial during hot or dry periods.

- Upgrading Sprinkler Heads: Switching to more efficient sprinkler heads, such as the Waterwise MP Rotator, can provide more uniform water distribution, helping to eliminate brown patches.

- Ensuring Head-to-Head Coverage: It’s crucial to achieve head-to-head coverage, where the spray from one sprinkler overlaps with the next. This ensures that every part of your lawn receives an equal amount of water, reducing the risk of dry spots developing. In some cases, adding additional sprinklers may be necessary to achieve this level of coverage and prevent brown patches effectively.

Dry Areas in the Garden

As plants grow, they can obstruct sprinkler coverage. Raising sprinklers or adding more units can help ensure water reaches the intended areas. Annual or biennial garden servicing, including trimming around sprinklers, is crucial for maintaining optimal irrigation coverage.

Garden Not as Healthy as It Could Be

Ensuring even and adequate water distribution is key. Regular maintenance checks and adjustments to the irrigation system can help address any disparities in water coverage, promoting a healthier garden.

Common Issues With Bore Systems That Need Repairing

Water Bore Suddenly Stops Working

If your bore system stops working, check for issues with solenoids not opening, the controller not sending signals, or broken wiring to solenoids. Installing a pressure relief valve can prevent damage by releasing excess pressure if a station stops working.

Sharing a Water Bore: Loss of Pressure

Sudden pressure loss in shared bore systems requires a check for leaks or system blockages. Collaborating with your neighbor to identify and address the issue can help restore proper function.

Bore System Has Lost Pressure

Run the system for a cycle and inspect for leaks, which could indicate a major issue. As pumps age, they may become less efficient, necessitating a professional evaluation.

Bore System with Intermittent Water Supply

Bore systems can run out of water, especially in areas with rock and clay. Monitoring water levels and consulting with a professional can help mitigate this issue.

Bore Has Lost Prime

A bore that has lost its prime needs repriming to function. Ensuring there’s water in the line allows the bore to effectively draw water up.

Uncommon Reticulation Issues That Need Repairing

Retic Works Intermittently

Intermittent functionality could be due to controller issues or corroded wiring. Professional diagnosis is recommended to pinpoint and fix the problem.

Half a Station Stops Working

This typically occurs when two valves are wired together and one fails or a wiring connection breaks. Inspection and repair by a specialist can resolve this issue.

More common reticulation issues

- Clogged Filter Screens – Filters can get clogged with debris, reducing water flow and affecting sprinkler performance. This is common in systems that use untreated water sources.

- Incorrect Timer Settings – Sometimes the issue is not mechanical but rather due to incorrect programming of the timer or controller, leading to overwatering, underwatering, or watering at the wrong times.

- Mismatched Sprinkler Heads – Different types of sprinkler heads deliver water at different rates. Mixing them on the same zone can lead to uneven watering, with some areas getting too much water and others not enough.

- Improper Zone Design – Zones that are not properly planned can lead to inefficient watering. For example, mixing plants with different water needs in the same zone can result in overwatering some plants while under-watering others.

- Backflow Preventer Issues – Problems with the backflow preventer can compromise the potable water supply, posing a health risk.

- Sprinkler Head Vandalism – In public or semi-public areas, sprinkler heads may be damaged due to vandalism.

- Root Intrusion – Tree or shrub roots can grow into piping and cause leaks or blockages.

- Electrical Surges – Electrical surges can damage controllers, solenoids, and other electrical components of the system.

- Weather Sensor Malfunctions – Some systems are equipped with rain or moisture sensors that adjust watering schedules based on weather conditions. Malfunctioning sensors can lead to overwatering or underwatering.

- Poor Drainage – Areas with poor drainage can become waterlogged, leading to soil erosion, plant diseases, and other issues.

General Tips for Preventative Maintenance

- Conduct Regular Inspections – Inspect your system regularly for signs of wear and tear, leaks, or other issues. Look for wet spots, dry spots, or areas of poor coverage.

- Clean Filters and Nozzles – Clean filters and nozzles regularly to prevent clogs and ensure optimal performance.

- Adjust Sprinkler Heads – Check sprinkler heads regularly and adjust them as needed to ensure proper coverage.

- Test the System – Test your system regularly to ensure it is functioning properly. Run each zone separately and check for leaks, clogs, or other problems.

- Monitor Water Usage – Keep track of your water usage and look for any sudden spikes or changes that could indicate a problem with your irrigation system.

- Schedule Professional Inspections – Consider scheduling regular inspections by a professional irrigation technician to identify and address any issues before they become serious problems.

If you’ve made it this far, congratulations! You should have all the tools you need for a healthy thriving lawn and a beautiful efficient reticulation set-up. If this all sounds just too complicated, or you want the best in the business to give your lawn or garden the love it deserves, then give Retic Renovation a call today!

Luke Porter

I have over 17 years hands-on experience in both landscaping and reticulation service and I’m extremely competent in problem solving, repairs, installation, and product knowledge.